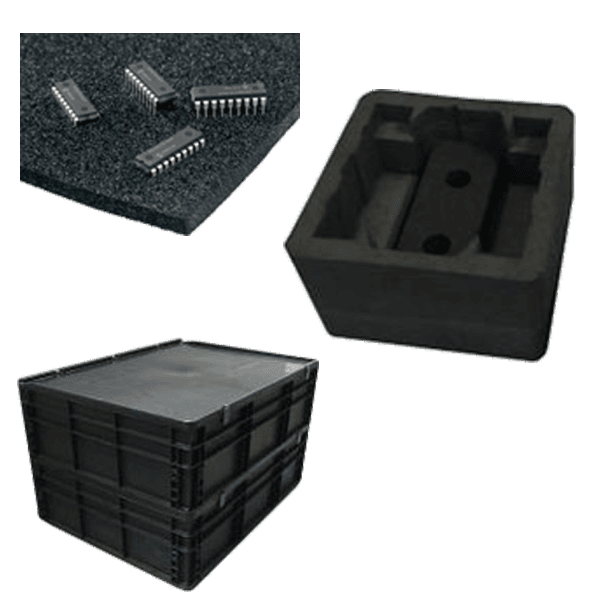

Electrostatic charge is most commonly created by the contact and separation of two materials and this can be a huge problem within the electronics industry. Critical devices and assemblies are susceptible to these static charges and the smaller IC circuitry is, the more vulnerable it is. Polyformes converts conductive and static dissipative foams to reduce these occurrences. Foam inserts in ESD cases or cartons, end caps, anti static clam shell foams and boxes - whatever you need protecting, we will produce it for you.

Conductive foam or static dissipative foam or anti-static that is the question…….

A static charge can be generated triboelectrically on all three types of material. The difference is the speed at which the static charge travels through the material when it makes contact with a conductive material or ground. This is a function of the resistivity of that material.

Conductive foams have ‘bulk’ or isotropic conductivity. They have a volume resistivity of less than 104 ohms.cms (10 to the power of 4) or a surface resistivity of less than 104 (10 to the power of 4) ohms/sq according to the ESD Association.

Static Dissipative foams offer a slower, more controlled transfer of a static charge and have volume resistivity in the range 104 (10 to the power of 4) - 1011 (10 to the power of 11) ohms.cms and surface resistivity between 104 and 1011 ohms /sq. These classifications vary between standards.

Anti-static foams are generally pink and are characterised by having a surface resistivity between 1010 10 to the power of 10) and 1012 (10 to the power of 12) ohms although some may have surface resistivity higher than this. They may have a degree of inherent conductivity but provide only limited protection from ESD events. Many rely on surface treatments to provide this conductivity. The dissipative performance of such materials is enhanced by increasing atmospheric humidity whereas static charge build-up becomes more of a potential problem as RH reduces.

Conductive, static dissipative and anti-static foams are available to suit every ESD protective requirement - Plastazote and Evazote conductive, Plastazote static dissipative and Ethafoam anti-static foams are available in a range of densities and are used for a multitude of applications; wafer interleaving, corner blocks, box liners, end caps and frames, munition packaging, standard and delicate lead devices, tote liners, wrist straps, bench mats and many more. The Azote foam ranges have outstanding beneficial properties for the electronics industry including consistent isotropic conductivity, halogen free, ROHS compliant, low outgassing, non-staining and non-corrosive, VOC free, excellent energy absorption, durability and lightweight.

We also have conductive containers in all sizes from the very small -34 x 34 x 8mm internal dimensions - up to the euro containers at 760x560x405mm internally.

The lifetime guaranteed Explorer Case, model 4419, has ESD certification. All other sizes of the waterproof, dustproof and shockproof Explorer Cases can be supplied ESD compliant for a minimum quantity depending on the model. For any ESD packaging, material or container enquiry, please contact us, we would be pleased to provide solutions to your requirements.