What are Azote Foams?

Azote is a group brand name for the high quality polyolefin foams made in their raw 'bun' or block form by Zotefoams, and converted into finished sheets and products by Polyformes Ltd. They include Plastazote, Evazote and Supazote, made from differing base polymers but manufactured using the same unique process.

Azote foams are odourless, flexible, strong, lightweight, water and chemical resistant and little affected when exposed to UV light. The original solid polymer blocks are expanded using a unique nitrogen gas process, so, unlike other foams expanded using chemicals, the Azote foams have no noticeable smell, are consistent, pure and inert and do not cause degradation, corrosion or staining. Most other foaming technologies use a chemical blowing agent that reacts and releases a gas within the plastic. Residues of these blowing agents remain within these materials and can detract from their physical properties and often causes staining and unpleasant odours. Azote foams use only nitrogen for foam expansion, in a process that creates unparalleled purity, isotropic consistency and closed cell protection. Because only nitrogen is used, no deleterious gases are present to seep out, no matter how long an item may be stored or archived.

The nitrogen saturation manufacturing process that enables the physical characteristics of the foam to be controlled precisely are explained in more detail below. Azote foams are available in densities from 15kg/m3 to 115kg/m3 in a wide range of colours that can be readily heat laminated together to produce eye-catching colour combinations.

The French chemist Antoine Laurent Lavoisier named nitrogen azote, meaning without life, and French chemists still use this name to refer to the element. AZOTE foams derive many of their exceptional properties directly from the use of this inert, tasteless, odourless gas in the environmentally friendly manufacturing process.

Azote foams are all made from polyolefins, which is a family of synthetic plastic materials that includes low density polyethylene (LDPE), co-polymers of ethylene such as ethylene-vinyl acetate (EVA) and high density polyethylene (HDPE). In detail the raw materials by grade are:

Plastazote® LD = Low Density Polyethylene

Plastazote® MP = Metallocene Low Density

Polyethylene Plastazote® HD = High Density Polyethylene

Evazote® EV = Ethylene-Vinyl Acetate (High VA content)

Evazote® VA = Ethylene-Vinyl Acetate (Low VA content)

Supazote® EM = Ethylene-Methyl Acrylate

These raw materials then dictate how the foam will feel and perform, for instance the HD grade foams (HDPE) are rigid, absorb high levels of energy and have good temperature stability, whereas an EV grade foam (EVA) is soft, resilient but lacks the high temperature stability.

Azote Foam Manufacturing Process

The manufacturing process comprises three essential stages:

(a) Mixing, extrusion and crosslinking

The polymer is blended in-line and extruded into solid sheet form. This sheet is then cross-linked, a process that enhances material strength, durability and temperature resistance. Crosslinking is effectively the formation of a lattice like structure at molecular level. It gives benefits in many areas such as thermal moulding. A high temperature window exists where crosslinked foams can be compressed or stretched and when cool they retain their shape. (Non crosslinked materials would collapse and melt at these temperatures.) The sheet is subsequently cut to size, ready for the gas solution process.

(b) Impregnation and saturation

The plastic slabs are loaded into a carriage system that feeds into high pressure autoclaves where they are heated above softening temperature in an atmosphere of pure nitrogen. Process temperatures of up to 250°C (482°F) and pressures of up to 10,000 psi (670 bar) combine to dissolve the nitrogen gas into the molecular structure of the softened plastic. Final cooling retains the nitrogen in the plastic.

(c) Final expansion

The nitrogen charged slabs are loaded into a low-pressure autoclave where the material is again heated above its softening temperature under moderate gas pressure. When this pressure is removed the nitrogen expands, physically foaming the soft plastic in a uniform manner.

The use of this unique manufacturing route enables foams to be produced from polymers such as HDPE and other technical polymers that could not be foamed easily using any other method. The separation of these manufacturing stages allows very accurate control of the individual parameters that govern the production of these high quality foams and contribute so fundamentally to their performance properties, cell size uniformity and consistency.

The superiority of Azote foams, compared with polyethylene foams made using other technologies, stems directly from the use of this high pressure gas technology. It produces a pure, low odour, chemically inert foam without blowing agent residues and with a uniform cell structure and regular cell walls.

Most other cross linked technologies use chemical blowing agents that react at temperature and release a gas into the plastic in order to create the foam. Residues of the chemicals blowing agents remain within these materials and can be seen with a relatively low level of magnification. The presence of these residues within foams can detract from their physical properties and can sometimes act as reactive impurities or contaminants. They cause an unwelcome odour and may even continue to react upon subsequent heating, further expanding the foam. Non cross linked foams have been expanded using ozone depleting CFCs, HCFCs, HFCs and more recently, flammable volatile organic compounds (VOCs).

No other manufacturing route can produce foam with such a consistent cell structure as that achieved with the Zotefoams process.

Cell size consistency is highly important for optimum workability, colour uniformity, impact absorption and physical performance predictability.

These photomicrographs show the cell structures of polyolefin foams made by different methods. Note the uniform and regular cell walls of the Plastazote and Evazote samples that give the foams their consistent and isotropic mechanical properties.

The small-scale imperfections in the chemically blown samples can seriously reduce the mechanical strength of the foam. Irregular cell structure can cause significant variation in density throughout these foams that, in turn, may lead to fabrication difficulties.

Benefits of Azote Foam Materials

Low weight - Weighing as little as 1.5% of the solid polymer, Azote® foams are ideal for many applications where weight is a cost penalty, from automotive to marine and aerospace.

Pure - The purity of Azote® foams makes them ideal for a range of hygienic applications in the healthcare field. It also makes Plastazote® the material of choice for protecting valuable artworks and museum pieces during storage and transit.

Water and chemical resistant - These inherent properties make Azote® foams ideal for a range of applications from automotive gaskets to expansion joints and eaves fillers for the building and construction industry.

Insulative - Azote® foams’ thermal and acoustic insulation properties are of benefit to the automotive, building and aircraft industries and encourage its use in cold weather camping mats.

Non corrosive - The use of pure nitrogen for expansion ensures Azote® foams (unlike chemically blown foams) have no corrosive residues, encouraging its use for long term protection of munitions and weapons.

High strength and durable - Much re-useable packaging depends on the durability of Azote® foam for its longevity. From dunnage to protective inserts for cases and boxes, Azote® foams are the natural preference.

Consistent - The high consistency and stress free nature of Azote® foams enables extremely complex shapes to be produced with great accuracy. Processing is easy and economical. Sheet material can be cut to 1.0mm thickness.

Easy to process - The consistency and crosslinking of Azote® foams makes them easy to manipulate and fabricate. Azote® foams are ideal for conversion using common thermoforming techniques.

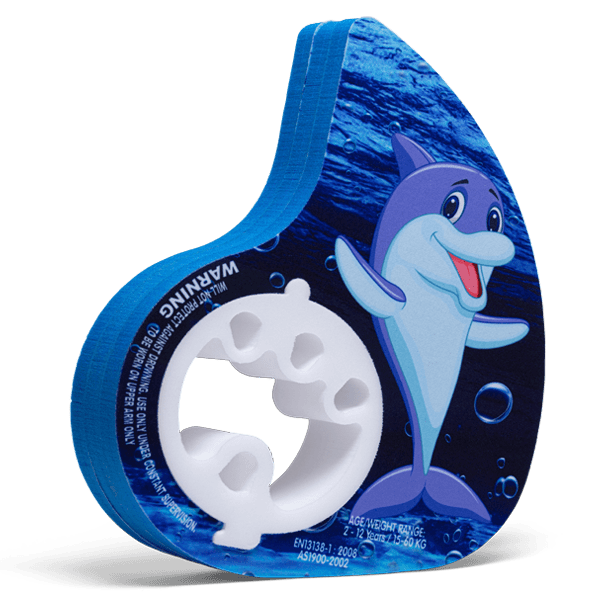

Buoyant - Suitable for many buoyancy applications from floating oil pipelines and boats to personal flotation devices.

Good aesthetics - Outstanding aesthetic properties add a further dimension to retail packaging protection. The colour depth and uniformity of Azote® foams are unmatched.

Good energy absorption - Sports protection benefits from Azote® foam’s energy absorbing properties as does a whole range of returnable packaging applications.

Flame retardant - Flame retardant grades are used in many aerospace applications such as aircraft seating.

Conductive and static dissipative - These special grades are highly suited to the protection and packaging of electronic equipment, assemblies and components for EMC/RFI shielding and gasketing.